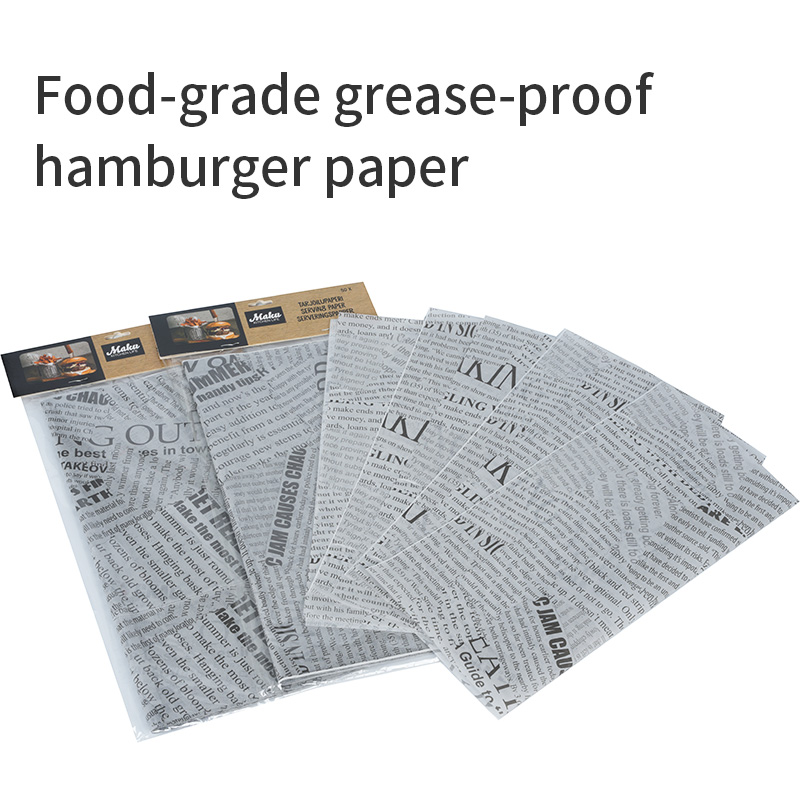

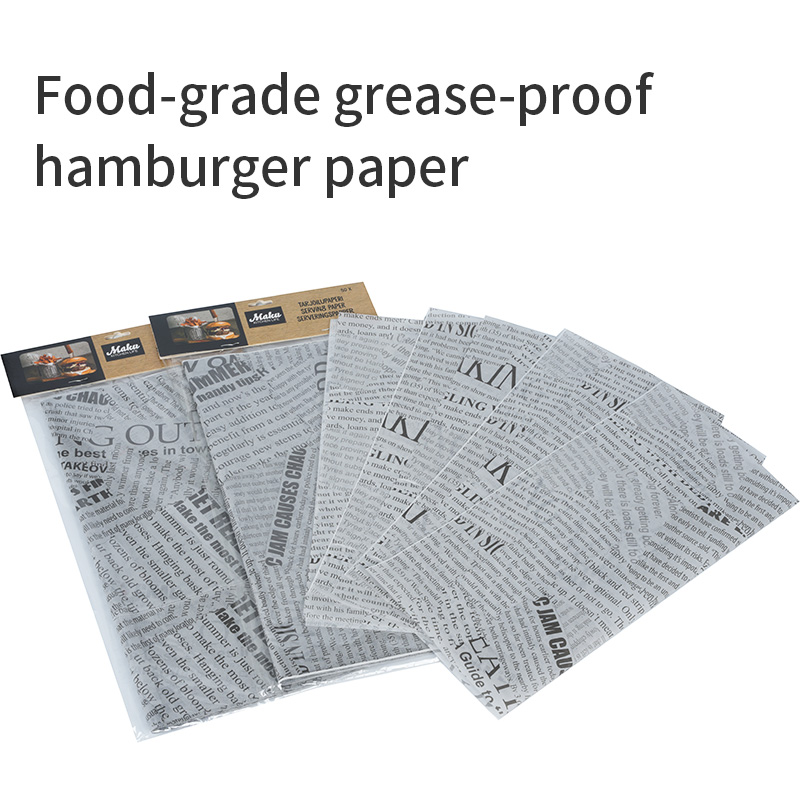

Food Packaging Paper

Product Introduction

In the fast food industry, quality burger paper means a lot to the dining experience and brand image. Our burger paper, carefully designed, excellent quality. Selection of food grade original wood pulp paper, safety and environmental protection, in line with standards. Paper stiffness and flexibility is good, stable and fit when wrapped, can prevent food from falling. It has excellent oil and water resistance, special coating can block oil, avoid stains, but also maintain moisture, maintain taste and freshness. Design can be customized pattern and brand identity, precision printing, to attract consumers, deepen brand impression. In addition, hamburger paper can be recycled, in line with the concept of environmental protection. Whether you are a fast food chain, food stand or catering business, choose our burger paper to upgrade the packaging and help you stand out from the competition and win the favor of consumers.

Specification

| Name |

Fast Food Packaging hamburger Paper |

| Glue Color |

Transparent/Custom |

| Feature |

Excellent oil resistance

high temperature resistance 180°

a wide range of uses

in line with food safety standards

easy to use

|

| Certification |

FDA

FSC

SGS

QS

ISO9001 certification

|

| Service |

1v1 |

| Private Label |

Supplied |

Feature And Application of Fast Food Packaging hamburger Paper

Features:

High quality material: selection of food grade original wood pulp paper, safety and environmental protection, in line with standards, stiffness and flexibility, stable and fit when wrapping, to prevent food from falling.

Excellent function: good oil and water resistance, special coating to block oil, prevent water loss, keep fresh taste.

Custom design: Support custom pattern and brand identity, precision printing, attract consumers, strengthen brand impression.

Environmentally friendly and recyclable: in line with the concept of sustainable development, recyclable.

Application scenario:

Fast food chain: unified hamburger paper printed with brand logo, strengthen brand image, easy to identify consumers.

Food stand: convenient for customers to take hamburgers, avoid hot hands and dirty clothes, customized packaging can attract customers.

Food and beverage enterprise takeout: to maintain the integrity and taste of the hamburger, exquisite packaging to enhance customer goodwill and re-purchase rate.

Event catering: Burger paper printed with event theme or sponsor information to meet packaging needs and help promote.

Detail of Fast Food Packaging hamburger Paper

Instructions:

Keep away from high temperature: Although hamburger paper has a certain heat resistance, do not directly contact the iron plate, oven and other high temperature equipment just out of the pot, to prevent the paper from burning or chemical changes affecting food safety.

Moisture-proof storage: hamburger paper is waterproof but not resistant to high humidity for a long time, should be stored in a dry and ventilated place, the packaged hamburger should not be placed in a humid environment for a long time, so as to avoid the paper becoming soft.

Strict control of printing: customized printing hamburger paper, be sure to ensure that the ink meets the food packaging standards, carefully check when receiving, if there is ink off, odor and other problems, timely contact the supplier.

Do not microwave: do not put hamburger paper directly into the microwave oven to heat, in case of burning or harmful substances, heating the hamburger should be taken out and replaced with a microwave oven suitable container.

Standard packaging: Wrap the burger tightly to avoid food exposure or soup leakage, but do not over-pull to prevent the paper from breaking.

Children supervision: When children eat hamburgers, parents need to supervise to prevent children from accidentally eating paper or playing with paper.

How To Use:

Preparation: Lay the clean hamburger paper flat on the working table, ensure that there are no wrinkles, and arrange the pattern or logo surface as required.

Place the burger: Place the burger horizontally in the center of the paper, so that the central axis of the burger roughly coincides with the center line of the long side of the paper, pay attention to stability, and prevent the food from slipping.

Fold the short side: Take the short side of the hamburger paper and fold it up 2-3 cm, cover the bottom edge of the hamburger, and press to fit.

Wrap side: Start from the long side of one side and wrap tightly along the side of the burger to the long side of the other side, pressing and fitting as you wrap.

Fold the other short side: Fold the other short side upward, and meet the previous short side at the top of the hamburger, and the excess paper plug the gap to fix.

Securing the finish: Wrap the remaining long side around the side of the burger, tucking the paper into the gap or securing with tape to ensure the burger is securely wrapped.

Product Qualification

Strict control of raw materials: Select high-quality raw fibers that meet food contact safety standards, suppliers are strictly audited, and each batch of raw materials is accompanied by authoritative testing reports to ensure stable quality.

Advanced technology: The use of international leading equipment and technology, in the completely closed dust-free workshop production, strict control of temperature and humidity, pressure and other parameters, such as unique oil-proof coating to enhance the oil-proof effect.

Full test: multi-channel test, from raw materials to finished products comprehensive test, using professional instruments to detect physical, chemical, microbial indicators, such as oil penetration, high temperature test.

Traceability improvement: each roll of paper has a unique traceability code, and problems can be quickly located raw materials, teams, dates, etc., to achieve accurate recall.

Continuous improvement: Professional R & D team collects feedback, analyzes requirements, and regularly upgrades processes and equipment to maintain quality leadership.

Authoritative attestation: through a number of international and domestic authority certification, such as SGS, FDA, FSC, EU, KOSHER, SMETA, QS, etc., provide strong endorsement for quality.

Deliver, Shipping And Serving

Professional ODM&OEM food packaging Products Manufacturer for 11 years. We appreciate cooperation with you.

FAQ

Q1: If OEM/ODM is available?

A1: Yes, OEM/ODM is available,including substance,color,size and package.

Q2: Do you provide sample? Free or charge?

A2: We can provide the sample free ,but you need to pay the freight charge.and if your sample is special,you also need to pay the sample charge.

Q3: What is your MOQ?

A3: Our MOQ is 3-5Tons with roll,200-500cartons with sheets of unprinting ,1000cartons with sheets of printing ,please kindly contact us for more detail.

Q4: Are you a trading company or a manufacturer?

A4: We are the original manufacturer for baking paper(sheets,jumbo roll,small roll,dim sum round ,printed parchment paper is all available over 10 years. Welcome to visit our factory.

Q5: what’s your delivery time?

A5: our delivery time is about 45dyas.

Q6: Do you have any certificates?

A6: our products passed inspection of SGS,FDA,FSC,EU,KOSHER,SMETA,QS,etc

Q7:What’s the payment term?

A7: We usually use T/T acceptable. when we sign the contract,the customers should deposit 30% of the payment ,the rest of the payment should be paid meeting against the copy of B/L or before the delivery .

English

English

Español

Español

Português

Português

русский

русский

français

français

日本語

日本語

Deutsch

Deutsch

Italiano

Italiano

Nederlands

Nederlands

ไทย

ไทย

Polski

Polski

한국어

한국어

Svenska

Svenska

magyar

magyar

Malay

Malay

Dansk

Dansk

Suomi

Suomi

Pilipino

Pilipino

Gaeilge

Gaeilge

عربى

عربى

norsk

norsk

čeština

čeština

Ελληνικά

Ελληνικά

فارسی

فارسی

Azərbaycan

Azərbaycan

slovenský

slovenský

Lietuvos

Lietuvos

Română

Română

मराठी

मराठी

Српски

Српски

Afrikaans

Afrikaans

עִברִית

עִברִית

Cymraeg

Cymraeg

Latvietis

Latvietis

icelandic

icelandic

Беларус

Беларус

Hrvatski

Hrvatski

Kreyòl ayisyen

Kreyòl ayisyen

Malti

Malti

Bosanski

Bosanski

ગુજરાતી

ગુજરાતી

Монгол хэл

Монгол хэл

Hmong

Hmong

Zulu

Zulu

Gàidhlig

Gàidhlig

Somali

Somali

O'zbek

O'zbek

Hawaiian

Hawaiian

Lëtzebuergesch

Lëtzebuergesch

Luganda

Luganda